設(shè)備概述

全自動高速粘箱機是我公司參考美歐日等國外的機型結(jié)合我國國情經(jīng)多年研制而成。本機可獨立工作,也可配合印刷開槽機作高速聯(lián)動線工作。

整機由智能化電腦一鍵式控制,輸入訂單后只需按下運行按鈕,各組合部自動調(diào)整規(guī)格尺寸,無需人工單獨調(diào)整。并有強大的記憶功能,可儲存9999個生產(chǎn)訂單,換單快,操作簡便,既能適應(yīng)大批量制作,又能適應(yīng)小批量多品種的生產(chǎn)。

Automatic high speed folder gluer is researched and manufactured by our company with the combination of forign technology and our national conditions.

Complete machine is controlled by one intellectualized key. Various sections will automatic adjust size by pushing one button without manual operation. It has strong memory functoion and can store 9999 orders. Changing order quickly and operating simply so that suits large quantity running ,also a few quantity but more variety running.

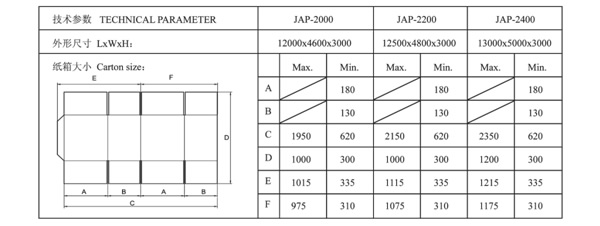

一:技術(shù)指標(biāo) technical parameter

機械最高車速:300張/分鐘Max. mechanical speed:?? 300 pieces/min

主電機功率Main motor power:22kw

裝機容量Total power:50.8kw

整機重量Weight:20噸

全電腦控制Computer control

觸摸屏輸入訂單,全自動調(diào)整規(guī)格Input order by touch screen, adjust spec automatically

側(cè)壓線以利折疊Side pressure line to make folding fine

真空吸附皮帶輸送防止紙板打滑,避免出現(xiàn)剪刀叉

Vacuum belt convey protect paperboard sliding to form shear fork

兩側(cè)置有成型導(dǎo)向輪

There are forming guiding wheels both side

進口美國VALCO噴膠系統(tǒng),自動跟蹤非接觸、準(zhǔn)確涂膠

Automatically tracking spray glue precisely without surface touching by spray glue system inport from VALCO USA

移動部件均有進口滾珠絲桿及直線導(dǎo)軌構(gòu)成

Moving parts consist of ball screw and straight line rail

伺服控制堆積、輸出,最高速度可達300張/分鐘

Server control stacking and eject to Max. speed 300 pieces/min

可獨立工作,也可配印刷開槽機

Independent running, also following printer and slotter

二:主要功能和配置 main function and configuration

1.進紙部:formfeed section

真空吸附前緣進紙,適合高速進紙 .

Lead edge feeder applying to high speed feeding

送紙精確,翹曲紙板均能正常運行

Feeding precisely even with warping paperboard

2.噴膠系統(tǒng):spray glue system

與國際知名品牌噴膠系統(tǒng)供應(yīng)商(VALCO)合作,確保在全世界各地都能得到良好售后服務(wù)。

Cooperate with the world famous supplier(VALCO) to ensure fine service anywhere.

美國VALCO最新一代噴膠系統(tǒng),無需任何設(shè)置,自動跟蹤非接觸性準(zhǔn)確涂膠。The newest spray glue system automatic apply glue precisely without surface touching and operating.

噴膠系統(tǒng)具有環(huán)保,無需擔(dān)心漏膠或溢膠,浪費少,維護和調(diào)整更加方便等特點。environmental protection and save glue, maintenance and adjusting conveniently.

3.折疊部:folding section

折疊部前傳送帶由上、下輸送帶夾著紙板前進。進紙囗間隙可電動調(diào)節(jié),上、下帶間隙自動調(diào)節(jié)。

paperboard be run forward by former convey belts consisted of upand lower belt. The gap of entrance and up and lower belt can be adjusted automatically.

折疊部入紙段壓輪采用彈簧加載,同時限位裝置可單獨調(diào)節(jié)每個壓輪與下折疊梁間隙。

Pressure wheels of entrance are loaded by springs.

送紙折疊部機身主要由左右二個大梁及下梁構(gòu)成,大小梁剛性強,穩(wěn)定性好,適合于機器的高速運轉(zhuǎn)。

Solid folding beams with strong rigidity and good stability suit high speed running.

為保證折疊準(zhǔn)確,設(shè)置了側(cè)壓線裝置。在二側(cè)折疊刀囗處設(shè)計安裝了針對折刀囗的側(cè)面壓線輪,以確保二次壓線的絕對準(zhǔn)確。

There are two set side pressure wheels against the folding knife to ensure folding lines precise.

折疊部后段傳送帶采用真空吸附帶輸送紙板前進以防止打滑差動形成剪刀叉。Back end convey belt with vacuum holes prevent sliding to form shear fork.

在折疊部后段裝有下折疊帶,速度高于真空吸附帶,對紙箱折疊面進行搓動,減少剪刀差。

Lower folding belt which speed is higher than vacuum belt avoid shear fork.

在折疊部二側(cè)裝有校正輪配合折疊帶實現(xiàn)精確折疊。

There are two set correcting wheels to ensure box square.

折疊梁左右移動采用電動調(diào)整,并可根據(jù)訂單自動調(diào)整。

Folding beams move left and right automatically according orders.

4.動力部:driving section

主動力采用變頻調(diào)速電機,與印刷機同步。

Frequency conversion motor runs synchronizely with printer.

所有動力均采用同步帶傳動,結(jié)構(gòu)簡單,噪音低,運行平穩(wěn),振動小。

All synchronism belts driving are structure simple, noise lower, running steady and vibrate lower.

移動部件均由進囗滾珠絲桿及直線構(gòu)成。

Moving parts are imported of ball screws and straight line rail.

5.高速計數(shù)堆積輸出部:high speed counting ,stacking and export section

采用光電開關(guān)精確計數(shù)。

Photoelectric sensor counting precisely

由三組伺服電機共同構(gòu)成高速運行下精確計數(shù)堆積輸出功能。

Three group of servo motor finish the function of precise counting ,stacking and transfering out while high speed running.

伺服控制高速分離桿確保按要求計數(shù)分堆。

Server control high speed separating bar to stack according required quantity per pile.

采用氣動輔助接紙桿,使紙箱堆疊更平整。

Pneumatic assistant supporting bars make boxes stacking flat.

氣動推紙機構(gòu)將堆疊好的紙箱整齊排出。

Pile boxes ejected by pneumatic pushing plate in order.

強力風(fēng)壓裝置防止從折疊部輸出時紙箱上翹,保證堆疊整齊,風(fēng)口方向可任意偏轉(zhuǎn)。

Strong wind pressure which direction can be adjusted anywhere protect boxes bend upwards.

后擋板部根據(jù)紙板規(guī)格可前后電動(自動或手動)調(diào)整。

Backboard motorized move adjusting (automatically or manually) according box’s spec.

上下輸送帶將整堆紙箱同步輸出。

Both up and lower convey belts transfer pile boxes together.

上輸送帶高度方向位置通過提升機構(gòu)自動(或手動)調(diào)整,根據(jù)每捆紙箱設(shè)定張數(shù)的不同,高度相應(yīng)變化.。

The height of up belt can be adjusted automatically or manually according the quantity per pile.

排出部可整體左右移動,保證紙箱始終落在機器中央。

Eject section can move to left and right to make boxes fall down on the center of table.

|